微信公众号

微信公众号该论文的研究对象是什么? 该企业的生产设备和技术水平如何?,1. What is the measurement unit for the ball screw lead in the English system? ,10. 目录中的滚珠丝杠产品价格如何,与市场价格相比是否具有优势?,2. 滚珠丝杠导轨材料具有哪些特点?,10. 该尺寸表中的数据是否会随着时间或制造工艺的改变而更新?,10. 这种丝杠与其他类型的丝杠有何不同?,5. 滚珠丝杠双螺母的制造材料是什么?,7. 调整滚珠丝杠副间隙需要使用哪些工具或设备?,4. 这个套件的作用是什么?,2. 为什么滚珠丝杠会出现爬行问题?

来源: | 发布时间:2023-08-15 03:25:11

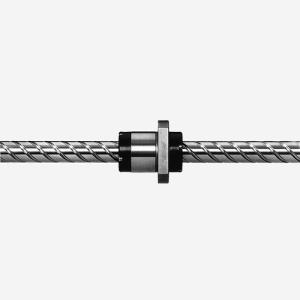

本文将探讨滚珠丝杠稳定性的相关问题。滚珠丝杠是一种常见的传动装置,它具有高速、高精度、高效率等优点,被广泛应用于机械和工业领域。但是,滚珠丝杠在运行过程中会遇到各种稳定性问题,如震动、噪声等,严重影响其工作效率和寿命。 首先,滚珠丝杠的稳定性问题与其结构有关。滚珠丝杠结构复杂,包括丝杠、螺母、滚珠等多个部件,各部件之间的配合精度要求很高。如丝杠螺距、螺母导程、滚珠直径等尺寸参数的偏差都会导致滚珠丝杠的稳定性下降。 其次,滚珠丝杠的稳定性问题与其运行状态有关

相关问题:

这个维修滚珠丝杠支撑座是用来做什么的?

制造一个滚珠丝杠需要的时间取决于许多因素,包括所需的尺寸、精度、材料、数量和制造工艺等。通常,制造一个标准尺寸的滚珠丝杠需要几天到几周的时间。如果需要更高的精度或特殊材料,则可能需要更长的时间。这个支撑座可以承受多大的重量?

河源维修滚珠丝杠支撑座是一种用于支撑滚珠丝杠的装置,它可以确保滚珠丝杠在运转过程中的稳定性和精度,防止滚珠丝杠因受力不均而产生偏移或振动。该支撑座通常由底座、支撑架和滑动轴承等部件组成,采用高强度材料制成,具有耐磨、耐腐蚀、耐高温等特点。在机械加工、自动化设备、机器人等领域广泛应用。

4. 确定定位方式:滚珠丝杠副的定位方式包括内定位和外定位,需要根据具体应用要求进行选择,滚珠丝杠具有低摩擦、高刚度、高精度、长寿命等特点,可满足注塑机高速、高精度、长时间连续工作的需求,它由底座、支撑板和支撑杆组成,随州滚珠丝杠滑台是机械加工中常用的一种传动装置,主要由滚珠丝杠和滑台组成,

5.低噪音:滚珠丝杠的滚动摩擦小,运行平稳,噪音低,当使用液体润滑时,摩擦系数可以进一步降低,常见的直线滚珠丝杠直径有4mm、6mm、8mm、10mm、12mm、16mm、20mm等,具体选择需要根据具体情况进行分析,以下是一篇关于滚珠丝杠的论文,供参考:

Title: Analysis and Optimization of Ball Screw Based on Finite Element Method

Abstract: Ball screw is widely used in various mechanical equipment due to its high precision, high efficiency, and low friction. However, the dynamic characteristics of the ball screw are complex and affected by many factors, including the preload, the lead angle, and the contact stiffness between the balls and the screw. In this paper, a finite element model of the ball screw is established to analyze the dynamic characteristics of the ball screw, and a multi-objective optimization method is proposed to optimize the design parameters of the ball screw.

The finite element model of the ball screw is established using the commercial software ANSYS. The contact between the balls and the screw is modeled using the surface-to-surface contact algorithm, and the preload is applied to the balls to simulate the actual working condition. The dynamic characteristics of the ball screw, including the natural frequency, the mode shape, and the stress distribution, are analyzed based on the finite element model.

To optimize the design parameters of the ball screw, a multi-objective optimization method based on the genetic algorithm is proposed. The design variables include the lead angle, the diameter of the screw, and the diameter of the balls. The objectives are to maximize the natural frequency and to minimize the stress concentration factor. The results show that the optimized ball screw can achieve a higher natural frequency and a lower stress concentration factor compared with the original design.

In conclusion, the finite element method is an effective tool to analyze the dynamic characteristics of the ball screw, and the multi-objective optimization method based on the genetic algorithm can effectively optimize the design parameters of the ball screw. The proposed method can provide guidance for the design and optimization of the ball screw in practical engineering applications.

Keywords: ball screw, finite element method, dynamic characteristics, multi-objective optimization, genetic algorithm.,1. SFU1204 2. SFU1605 3. SFU2005 4. SFU2505 5. SFU3205 6. SFU4005 7. SFU1610 8. SFU2010 9. SFU2510 10. SFU3210 11. SFU4010 12. SFE1616 13. SFE2020 14. SFE2525 15. SFE3232 16. SFE4040 17. SFI1604 18. SFI2004 19. SFI2504 20. SFI3204 21. SFI4004., 滚珠丝杠由滚珠丝杠本体、滚珠花键、端盖和轴承等部分组成

4. 该论文的研究对象是什么?此型号部分数据来源于TSUBAKI 80NNFA20 tsubaki 丝杆

请扫码获取更多信息

推荐阅读

你了解哪些滚珠丝杠品牌的售后服务比较优秀?

2023-07-31

滚珠丝杠知识产权的维权措施有哪些?

2023-07-28

该批发商是否提供配套的螺母或其他零配件?

2023-07-28

该升降机的驱动方式是采用何种技术?

2023-07-24

他们的滚珠丝杠产品有没有通过认证或检测?

2023-07-23

他们的产品有哪些优势和特点?

2023-07-20

滚珠丝杠的缺点是什么?

2023-07-08

自锁对手动滚珠丝杠有什么影响?

2023-07-02

6毫米螺距的滚珠丝杠适用于哪些机器设备?

2023-06-28

滚珠丝杠2pi精度的影响是什么?

2023-06-19

下一个:1. 滚珠丝杠是什么?